-

- Products

- Indoor Household Cords

- Appliance Cords

- General Purpose Short-Length Cords

- General Purpose Extension Cords

- Landscape & Decorating Cords

- Bright Color Extension Cords

- Oil-Resistant Extension Cords

- Cold-Flex Extension Cords

- VividFlex Power Cords

- EXTREME All-Weather Cords

- Cord Management

- Task Lights

- Adapters & GFCI Devices

- Where to Buy

- About

- Careers

- Glossary

- Catalog

- Products

- Indoor Household Cords

- Appliance Cords

- General Purpose Short-Length Cords

- General Purpose Extension Cords

- Landscape & Decorating Cords

- Bright Color Extension Cords

- Oil-Resistant Extension Cords

- Cold-Flex Extension Cords

- VividFlex Power Cords

- EXTREME All-Weather Cords

- Cord Management

- Task Lights

- Adapters & GFCI Devices

- Where to Buy

- About

- Careers

- Glossary

- Blog

-

-

Top 10 Appliance Cables You Need for Safe and Efficient Use

In today's fast-paced world, the role of appliance cables has never been more critical. As we incorporate various electronic devices into our daily routines, ensuring their safe and efficient operation becomes paramount. An appliance cable serves as the vital link between your devices and power sources, and selecting the right one can significantly impact both performance and safety. With the potential hazards associated with faulty or incompatible cables, understanding the essential features and types of appliance cables is crucial for every consumer.

This article presents a comprehensive overview of the top 10 appliance cables you need to consider for optimal functionality. By exploring the characteristics that make each cable suitable for different appliances, we aim to equip you with the knowledge needed to make informed choices. Whether you are upgrading your home setup or simply replacing a worn-out cable, knowing what to look for will help you ensure that your appliances operate safely and efficiently. Let’s delve deeper into the intricacies of appliance cables and discover how to enhance your electronic experience.

Table of Contents

[Hide]

Top Types of Appliance Cables: Understanding Specifications and Uses

When it comes to selecting appliance cables, understanding their specifications and uses is crucial for safety and efficiency. Appliance cables are designed to handle varying levels of current and voltage depending on the application. For instance, heavy-duty cables, often used for high-power appliances like dryers and air conditioners, must be rated for a minimum of 30 amps to ensure they can handle the load without overheating. In contrast, lighter cables may suffice for small kitchen appliances or tools, typically requiring ratings of 10-15 amps.

Another important aspect to consider is the construction of the cable itself. Cables can be either ungrounded or grounded, with the latter providing an additional layer of safety by redirecting excess current away from users. Moreover, the gauge of the wire within the cable plays a significant role in its efficiency; thicker wires (lower gauge numbers) reduce resistance, which minimizes energy loss during operation. By understanding these specifications, users can select the appropriate appliance cable suited for their needs, ensuring both efficiency and safety in their daily operations.

Safety Standards in Appliance Cables: NEC Guidelines and Compliance

When it comes to appliance cables, adhering to safety standards is crucial for ensuring both efficient operation and user safety. The National Electrical Code (NEC) sets forth specific guidelines that govern the construction and use of appliance cables. These guidelines help reduce the risk of electrical hazards, such as overheating and fire, by mandating the use of materials that can withstand certain environmental conditions. Compliance with NEC standards not only promotes safety but also ensures that appliances operate at their optimum capacity.

Moreover, NEC guidelines address various factors, including the cable's insulation rating, voltage capacity, and the appropriate environment for its use. For instance, cables used in damp or wet locations must have suitable insulation to prevent moisture ingress, which can lead to short circuits or electrocution. Additionally, NEC-dictated wire gauges relate to the amperage the cable must handle, further safeguarding against potential overloads. By following these established standards, users can significantly reduce the likelihood of electrical accidents, prolong the lifespan of their appliances, and maintain a safe home or workplace environment.

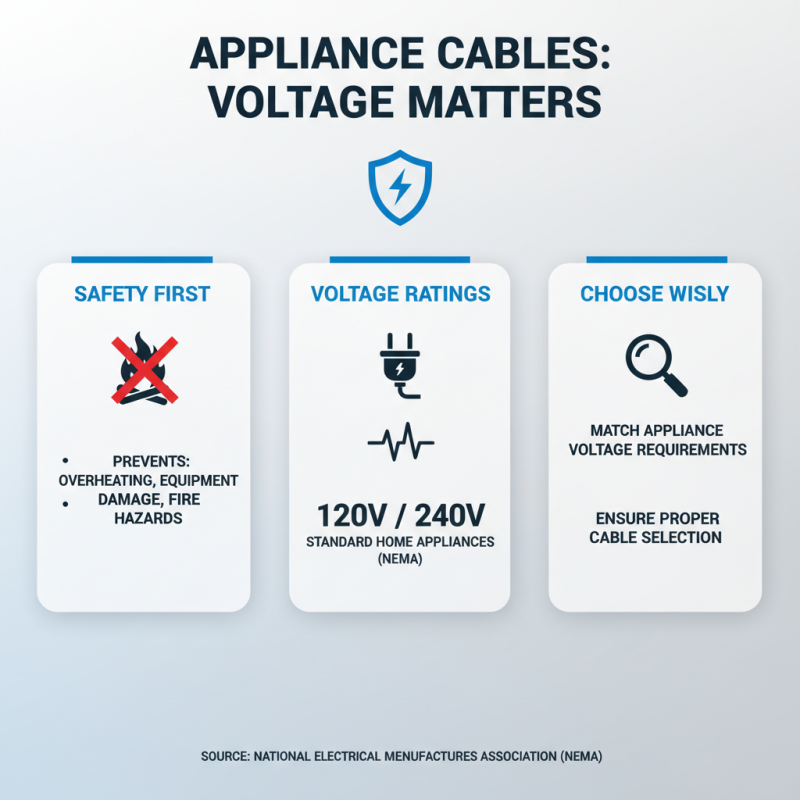

Voltage Ratings: Choosing the Right Cable for Household Appliances

When it comes to household appliances, selecting the right appliance cables is crucial for ensuring both safety and efficiency. Voltage ratings are a key factor to consider during this selection process. According to the National Electrical Manufacturers Association (NEMA), the majority of home appliances operate on standard voltage levels of 120V or 240V. A mismatched voltage rating can lead to overheating, equipment damage, or even fire hazards. Thus, understanding the specific voltage requirements for each appliance is the first step in choosing the proper cable.

Additionally, performance testing reports from the International Electrotechnical Commission (IEC) indicate that cables used for high-power appliances, like ovens or refrigerators, should have a higher ampacity rating. For example, cables rated for 15 amps can support most kitchen appliances, but those requiring 30 amps will necessitate thicker, more robust wiring to manage the increased load. It is also advisable to consider insulation types and their temperature ratings; thermoplastic elastomers (TPE) and polyvinyl chloride (PVC) are commonly used materials that provide good insulation and durability. By aligning voltage ratings and cable specifications with appliance requirements, homeowners can ensure safe and efficient operation, thereby prolonging the life of their electrical appliances.

Cable Materials: How Wire Composition Affects Performance and Longevity

When it comes to selecting appliance cables, understanding the materials used in their construction is crucial for ensuring safe and efficient performance. The composition of the wire directly affects both the functionality and longevity of the cable. For instance, copper is one of the most common materials used due to its excellent conductivity. According to the International Electrotechnical Commission (IEC), copper cables outperform aluminum in electrical performance, offering lower resistance and reducing energy loss. Cables made from high-quality copper can maintain their efficiency for years, potentially extending the lifespan of the appliances they power.

Another important aspect is the insulation materials used in these cables. Thermoplastic elastomers (TPE) and polyvinyl chloride (PVC) are widely utilized for their durability and resistance to environmental factors such as heat, moisture, and abrasion. A study by the National Electrical Manufacturers Association (NEMA) highlights that cables with superior insulation significantly reduce the risks of electrical faults and hazards, ultimately contributing to greater user safety. Furthermore, quality insulation can withstand extreme temperatures, with some types rated for use in conditions up to 90°C, enhancing reliability in both residential and industrial applications. Selecting appliance cables with the right materials not only ensures optimal performance but also safeguards investments in electrical appliances by minimizing wear and tear over time.

Top 10 Appliance Cables You Need for Safe and Efficient Use

| Cable Type | Wire Material | Gauge (AWG) | Max Current (A) | Temperature Rating (°C) | Expected Lifespan (years) |

|---|---|---|---|---|---|

| Heavy-Duty Extension Cable | Copper | 10 | 30 | 75 | 10 |

| Indoor Appliance Cable | Aluminum | 14 | 15 | 60 | 8 |

| Outdoor Power Cable | Copper | 12 | 20 | 85 | 10 |

| Flexible Appliance Cord | Copper | 16 | 13 | 70 | 5 |

| Heavy-Duty Generator Cable | Copper | 6 | 50 | 90 | 15 |

| SAA Certified Neoprene Cable | Copper | 10 | 30 | 75 | 10 |

| Low-Voltage Appliance Wiring | Copper | 18 | 10 | 60 | 8 |

| Waterproof Power Cable | Copper | 12 | 25 | 80 | 10 |

| High-Temperature Appliance Cable | Copper | 10 | 20 | 150 | 20 |

| Cooling-Fan Power Cable | Copper | 20 | 5 | 50 | 7 |

Future Trends in Appliance Cables: Innovations in Safety and Efficiency

The future of appliance cables is being shaped by a combination of technological innovations and an increasing emphasis on safety and efficiency. Recent studies predict that by 2025, the demand for advanced appliance cables will see a growth rate of over 8% annually, driven largely by the rise of smart home technology and energy-efficient appliances. Manufacturers are focusing on integrating materials that not only enhance durability but also comply with stricter safety regulations, which have become more prevalent in recent years. For example, the International Electrotechnical Commission (IEC) has introduced new standards that require cables to withstand higher temperatures and resist potential hazards, such as short circuits and overloads.

Furthermore, innovation in insulated materials is becoming a focal point in the development of appliance cables. According to a report from the Electric Power Research Institute, cables made from advanced thermoplastic elastomers and cross-linked polyethylene offer significant advantages, including improved flexibility and reduced risk of electrical failure. These materials also provide better thermal management, which is crucial for maintaining efficiency in high-performance appliances. As more consumers demand products that are not only functional but also environmentally friendly, the industry is pivoting towards recyclable materials and energy-efficient manufacturing processes. This evolution not only aligns with global sustainability goals but also ensures a safer operating environment for consumers.

Top 10 Appliance Cables: Safety and Efficiency Ratings

Related Posts

-

2025 Top 5 Short Power Cords: Compact Solutions for Every Device

-

10 Essential Tips for Choosing the Right Cord Cable for Your Devices

-

How to Organize and Manage Electronic Cords for a Clutter Free Space

-

Transform Your Space: 7 Stylish and Functional Cool Extension Cords You Didn’t Know You Needed

-

How to Organize and Manage Your Cords and Cables Effectively

-

How to Choose the Right Power Cord Cable for Your Electronics with Expert Tips